X-100 Administration Building

The X-100 Administration Building was the main hub for the management of the Portsmouth Gaseous Diffusion Plant. This two-story building was built with wings in four directions surrounding a secure three-level...

Learn More

X-101 Dispensary Building (Hospital)

The X-101 Dispensary Building (Hospital) was the on-site facility where plant personnel could get most medical care in connection with the plant operation. Employees went there for routine yearly check-ups, were fitted...

Learn More

X-102 Cafeteria

X-102 was an employee cafeteria with dining areas that could be separated and used to host more private gatherings such as employee recognition dinners, or for guests visiting the plant. Breakfast and lunch were served each day to hundreds of employees. A rotating menu...

Learn More

X-103 Auxiliary Office Building

The former X-103 Auxiliary Office Building, constructed in 1954, was located within the core GDP area. The X-103 Auxiliary Office Building housed the PORTS respirator facility where respirators were issued and cleaned...

Learn More

X-104 Guard Headquarters

The X-104 Guard Headquarters has served as the headquarters for the plant’s protective force since its construction in 1954. It also houses administrative offices and training areas. It is a 10,600-sq ft concrete and concrete block building with offices, training room...

Learn More

X-108B Security Portal

The X-108 security portals were manned by security personnel and used as checkpoints for workers, visitors, and equipment entering and exiting controlled areas of the plant site. The X-108B security portal, also known as the North Portal, is one of three remaining original portals...

Learn More

X-111A/B Special Nuclear Material (SNM) Monitoring Portals

The X-111A and X-111B (SNM) Monitoring Portals are security portals used for safety screening of employees and equipment entering and exiting the X-326 Process Building...

Learn More

X-230J2 South Environmental Sample Station

The X-230J2 South Environmental Sample Station houses equipment for composite water sampling for the South Holding Pool effluent, as well as equipment to support ambient air monitoring...

Learn More

X-300 Plant Control Facility

The X-300 Plant Control Facility provided all control, instrumentation, and communication equipment required for supervision, direction, and coordination of overall plant operations in one central location. The exterior walls, roof, floor slabs, stairs, tunnels, vault...

Learn More

X-300A Process Monitoring Building (Computer Building)

The X-300A Process Monitoring Building, formerly known as the “Computer Building,” is located just west of the circular-domed X-300 building. The building originally housed the Cascade Automatic Data Processing (CADP) and the central...

Learn More

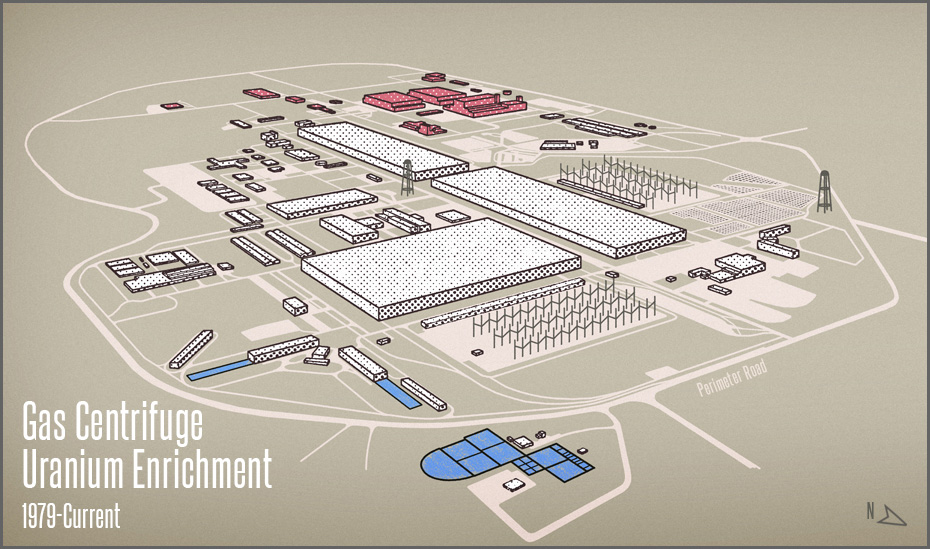

X-326 Process Building

Construction of the X-326 began in 1952. The final unit was completed and turned over on February 3, 1956. The primary differences between the X-326 process system and the systems in the X-330 and X-333 were that the stage compressors were centrifugal rather than axial flow...

Learn More

X-330 Process Building

Construction of the X-330 began in 1952. The final unit was completed and turned over on July 14, 1955. The equipment in the X-330 was similar to that of the X-333 except for necessary size and capacity changes to service the installed process equipment...

Learn More

X-333 Process Building

Construction of the X-333 started in 1952. The final unit was turned over on November 4, 1955. The X-333 building housed the largest of the enrichment process equipment. The facility housed eight units of 33 or “000” size (640 stages) equipment. Since the X-333 equipment served...

Learn More

X-342A Feed, Vaporization, and Fluorine Generation Facility & X-342B Fluorine Storage Building

Designed and built by the Peter Kiewit Sons’ Construction Company, the X-342A is used...

Learn More

X-343 Feed & Sampling Facility

Construction began in 1978 and the facility became operational on June 1, 1982. It was designed to vaporize UF6, which had been received in 10 and 14 ton cylinders in a solid state, before feeding to the cascade for enrichment...

Learn More

X-344A Feed Manufacturing/ UF6 Sampling Facility

Construction of the X-344A began in 1952 and was completed some time in 1957. The X-344 was originally designed as a feed manufacturing facility to produce Uranium Hexafluoride (UF6) from Uranium Tetrafluoride (UF4)...

Learn More

X-344B Maintenance Storage Building (Ash Storage Facility)

The former X-344B Maintenance Storage Building (Ash Storage Facility) was designed and built by the Peter Kiewit Sons’ Construction Company and was demolished in 2011...

Learn More

X-530 Switchyard Facilities

The X-530 Electrical Switchyard Complex is located west of the X-330 Process Building and south of the former X-630 Cooling Towers. This switchyard area, including the switch houses and control house, oil house, the test and repair facility, the valve houses, and oil pumping station...

Learn More

X-533 Electrical Switchyard

In an arrangement made between the Portsmouth Gaseous Diffusion Plant and the Ohio Valley Electric Corporation (OVEC), the X-533 Electrical Switchyard complex was one of two high voltage switchyards that together provided up to 2,200 megawatts of power...

Learn More

X-600 Steam Plant

The X-600 Steam Plant was built between February 1953 and September 1954 to provide all the steam required for process and building heating purposes, cleaning equipment and various other uses throughout the gaseous diffusion plant. The building was upgraded...

Learn More

X-611 Water Treatment Plant

The X-611 Water Treatment Plant has the design capacity to process 40 million gal/day but typically processed over 10 million gal of water daily for the plant’s recirculating cooling water system when the gaseous diffusion plant was in operation...

Learn More

X-612 Elevated Water Tank

The X-612 Elevated Water Tank is located near Perimeter Road on the west side of the PORTS site. The X-612 Elevated Water Tank is a sanitary water storage and head tank that provides a source of water for the Sanitary Fire Water system which services the plant...

Learn More

X-626 Recirculating Water Pump House and Cooling Tower

The X-626 Recirculating Water Pump House and Cooling Tower (i.e., X-326 Process Building cooling system) consists of approximately 2,340 coolant evaporators, 200 coolant condensers...

Learn More

X-700 Convertor Shop and Chemical Cleaning Facility

The building is divided into two main sections. The east section is the cleaning area; the west section houses the converter shop, which is divided into three subsections: the north half, the south half, and the west addition...

Learn More

X-705 Decontamination Building

During the Cold War, this building housed equipment for the disassembly and decontamination of process equipment, for uranium recovery, and for plant laundry. The facility is centrally located to the...

Learn More

X-710 Technical Services Building

The laboratory in the X-710 Building provided mass spectrometry analysis for determining assays of samples and analysis for minor isotopes. In addition, the laboratory provided wet chemistry and other analyses...

Learn More

X-720 Maintenance and Stores Building

The X-720 Maintenance and Stores Building was centrally located near three process buildings (Figure 130). It was designed to: (1) permit maintenance of process and auxiliary equipment, (2) house the spare parts...

Learn More

X-744H Bulk Storage Building

The X-744H Bulk Storage Building, also known as Warehouse #18, is a 58,700-square-foot steel frame building with a concrete slab floor that was built in 1953. The X-744H Bulk Storage Building was originally used as a fabricating shop and workshop in 1953 and 1954...

Learn More

X-746 Shipping & Receiving Facility

The X-746 was a one floor, steel frame building, constructed in 1954. It was originally designed to be the Uranium Material Handlers Building, but instead was used as a high assay shipping and receiving building from the 1950s until about 1971...

Learn More

X-760 Building

Construction of the X-760 was completed on April 27, 1954. It was used as a chemical test and small-scale instrumentation test building to improve the gaseous diffusion process. Methods to recover uranium from solutions, studies of uranium hexafluoride releases...

Learn More

X-770 Mechanical Testing Building

The X-770 Mechanical Testing Building was constructed in 1955. The two-story building provided research and development testing, and was designed to evaluate the performance and reliability of compressors...

Learn More